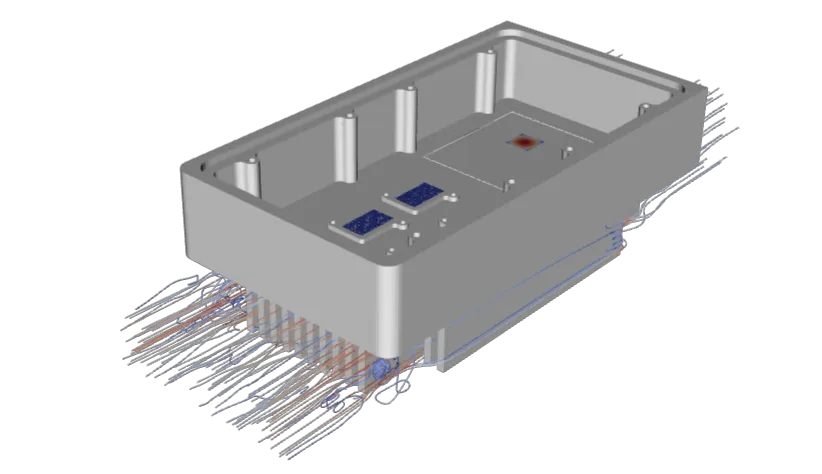

Our cutting-edge Computational Fluid Dynamics (CFD) software gives you the power to simulate, analyze fluid flow, temperatures, pressure, and beyond, as well as visualize your design.

%20(1)%20(1)%20(1)%20(1)%20(1)%20(1)%20(1).png)

CFD is a part of fluid mechanics that utilizes data structures and numerical calculations to analyze and solve fluid (gases and liquids) flow problems like chemical compositions, density, and velocity.

Built upon OpenFOAM libraries, our ColdStream proprietary CFD engine provides customers with accurate and detailed results through innovative CFD software that can analyze a range of problems related to laminar and turbulent flows, incompressible and compressible fluids, multiphase flows, and much more.

Conduction is the most basic form of heat transfer, and can be defined as the energy transfer by direct contact inside or between different objects through molecular vibration and collisions.

Heat transfers through molecular collisions from higher to lower temperature regions, with faster molecules colliding with slower ones and increasing the temperature of the lower region.

Materials with high thermal conductivity, such as metals, conduct heat quickly, while materials with low thermal conductivity, such as insulation materials, conduct heat slowly.

Solids are better at heat transfer because their molecules are packed tightly and can easily pass on energy through collisions.

Fluids are less efficient because they can only transfer heat through bulk motion and conduction.

Learn more using Diabatix's innovative CFD software.

Convection is one of the three main heat transfer mechanisms, conduction, and radiation. Convective heat transfer refers to the transfer of heat through a fluid, such as air or water, through bulk fluid movement of energy by the actual motion of matter.

This motion can be triggered by an external force (pump, fan, boundary) or by buoyancy. In convection, heat is transferred through a fluid by moving hot fluid particles from a higher-temperature region to a lower-temperature region.

This occurs through two types of convection: natural convection and forced convection. Understanding convection is important in thermal analysis as it affects heat transfer in many engineering and scientific applications.

The heat transfer rate by convection depends on several factors, such as the fluid properties, the temperature difference between the surface and the fluid, and the flow velocity; which can be evaluated using Diabatix's CFD analysis software.

Radiation is one of the three main heat transfer mechanisms.

It refers to heat transfer through electromagnetic waves, such as light or infrared radiation.

Radiation requires the objects to be transparent.If not, the energy is immediately absorbed in the interface of the body.

In thermal analysis, radiation can be important in situations where there is no physical contact between two objects, or when heat is transferred through a vacuum.

In engineering applications, radiation heat transfer is important in the design of thermal insulation, solar panels, and radiative cooling systems.

It is also essential in analyzing thermal radiation emitted by electronic components (using CFD analysis software), as it can cause overheating and affect their performance.

Buoyancy is a phenomenon in fluid flow where a fluid exerts an upward force on an object placed in it, which is known as the buoyant force.

This fluid flow force is due to the difference in density between the object and the fluid, and it is described by Archimedes' principle driven solely by a density difference due to a temperature gradient.

Buoyancy is significant in many fluid flow applications, including ship and submarine design, hot air balloons, and ocean currents.

It is also important in natural phenomena, such as the movement of tectonic plates and the formation of clouds in the atmosphere.

In addition to buoyancy, fluid flow can also be affected by other forces, such as drag, lift, and pressure forces.

Understanding these forces is important in many engineering applications, including the design of aircraft, wind turbines, and piping systems.

Modeling temperature-dependent properties is an essential aspect of thermal analysis and CFD simulations.

Many materials exhibit significant variations in their properties, such as thermal conductivity, specific heat, and viscosity, as the temperature changes.

To accurately model temperature-dependent properties, you need to collect data, determine the model (polynomial model, the exponential model, and the power law model, etc.), implement the model with a defined temperature range and coefficients, perform CFD simulations to calculate heat transfer rates or heat flux, temperature distributions, and other important parameters, and finally validate these results.

By accurately modeling these properties through CFD simulation using a trusted CFD software, engineers and scientists can obtain more accurate results and make better-informed decisions about the design and performance of their systems.

Evaluating turbulent flow with thermal CFD simulations can provide important insights into the behavior of fluid movements, especially regarding heat transfer.

Turbulent flow is characterized by chaotic and unpredictable fluid motion, which can result in enhanced mixing and heat transfer.

Thermal CFD simulation through trusted CFD software can help to predict the temperature and flow fields in turbulence modeling, providing engineers and scientists with a detailed understanding of how heat is transferred within a system.

Within aerodynamics, much of what you are solving is Reynolds-Averaged Navier-Stokes (RANS) equations with additional applied computational techniques such as direct numerical simulation (DNS), and large eddy simulation (LES) as considerations in the computational field of aerodynamics. Turbulence modeling and evaluating turbulent flows in the simulation of fluid flows, a series of RANS-based turbulence models are available.

Numerical methods in Computational Fluid Dynamics (CFD) are mathematical techniques used to simulate the behavior of fluids using computers. CFD is a branch of fluid mechanics that deals with the numerical simulation of fluid movement and heat transfer phenomena. Some common numerical methods used in CFD simulations include:

Numerical methods in CFD are continually evolving, and new methods are being developed to handle increasingly complex fluid flow problems. The choice of numerical method depends on the problem being solved and the available computational resources within CFD software.

CFD analysis and FEA are both numerical methods used to simulate physical systems. However, they are used to solve different types of problems.

CFD software primarily analyzes fluid flows, including fluid velocity and flow of liquids and gases. CFD simulations involve solving a set of governing equations, including the Navier-Stokes equations, to predict the behavior of the fluid. The methods used in CFD include finite volume, finite difference, and spectral methods. CFD is used in various aerospace, automotive, and energy systems applications.

FEA, on the other hand, is used to analyze stresses and deformations in solid structures. FEA simulations involve dividing a complex structure into smaller, simpler elements and solving the equations for each element. The method is used to predict the behavior of the structure under different loading conditions. FEA is used in various applications, including civil engineering, automotive, and aerospace.

The main difference between CFD analysis and FEA analysis is the type of problem they are used to solve. CFD software is used to analyze fluid flows, while FEA is used to analyze solid structures. While the methods used in CFD analysis and FEA analysis are similar in some respects, the governing equations and numerical techniques used are different. The type of output generated from the simulations is different; CFD generates flow fields and velocity distributions, while FEA generates stress and deformation fields in solid structures.

The Navier-Stokes equation is a set of partial differential equations describing fluids' motion, and essentially acting as the result of the known laws for the behavior of viscous fluids. These Navier-Stokes equations are named after the French mathematician and physicist Claude-Louis Navier and the Irish mathematician and physicist George Gabriel Stoke, and are derived from mass, momentum, and energy conservation laws.

Typically, the Navier-Stokes Equation is typically not solved explicitly due to its mathematical complexity. Various techniques exist to approximate the solution computationally. Instead, applications of these equations are commonplace in CFD in techniques, such as the finite volume method (FVM), finite difference method (FDM), finite element method (FEM), and various spectral methods. One way to consider the groupings of equations at work in the Navier-Stokes equations is to describe them as the convection, momentum, and diffusion equations.

Fluid-structure interactions (FSI) refer to the interaction between a fluid flow and a solid structure. When a fluid flows around or through a solid object, it can exert forces on the object, which can cause it to deform or vibrate. In turn, the deformation or vibration of the object can affect the fluid flow, leading to changes in the fluid's behavior.

FSI is important in many engineering applications, including aerospace, civil engineering, and biomedical engineering. For example, FSI can affect aircraft and spacecraft aerodynamic performance in aerospace engineering. In contrast, in civil engineering, FSI can affect the stability and integrity of structures subjected to wind and water loads. In biomedical engineering, FSI can affect the flow of blood in arteries and veins, and the behavior of medical devices such as stents and heart valves.

To analyze FSI, it is necessary to use a combination of fluid dynamics and solid mechanics. Computational fluid dynamics (CFD) analysis can be used to model the fluid flow, while finite element analysis (FEA) can be used to model the solid structure. Coupling these two simulations allows the effects of FSI to be studied.

Understanding FSI is important for designing and optimizing structures and systems that interact with fluids. By modeling and analyzing FSI, engineers can optimize the design of structures to reduce the effects of fluid-induced vibrations or deformation, and to improve the performance and safety of these structures. Luckily, ColdStream makes this easier than ever before.